Walden Environmental Engineering and Harkin Aerial Fly Through Part 360 Compliance

As we all try to reduce our lasting impact on the planet, it is becoming more common for municipal Sanitation Departments and private solid waste facilities in New York state to process yard wastes for reuse as mulch, keeping this material from landfill.

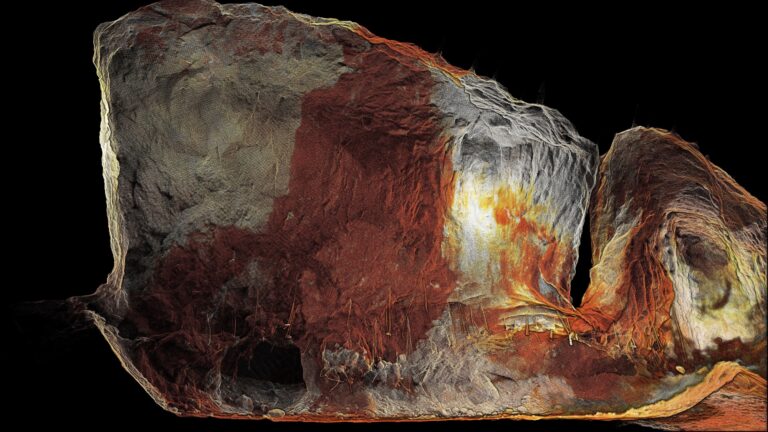

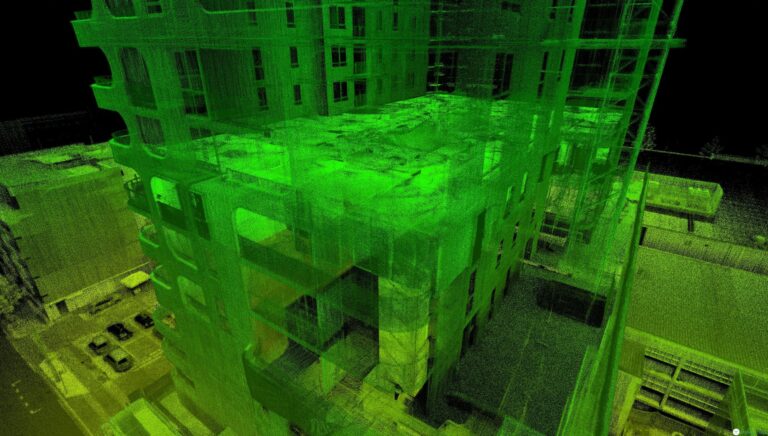

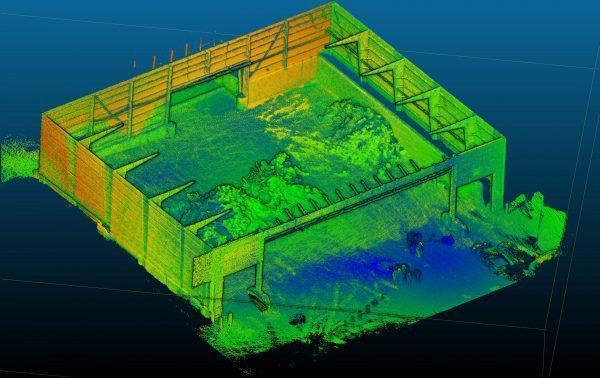

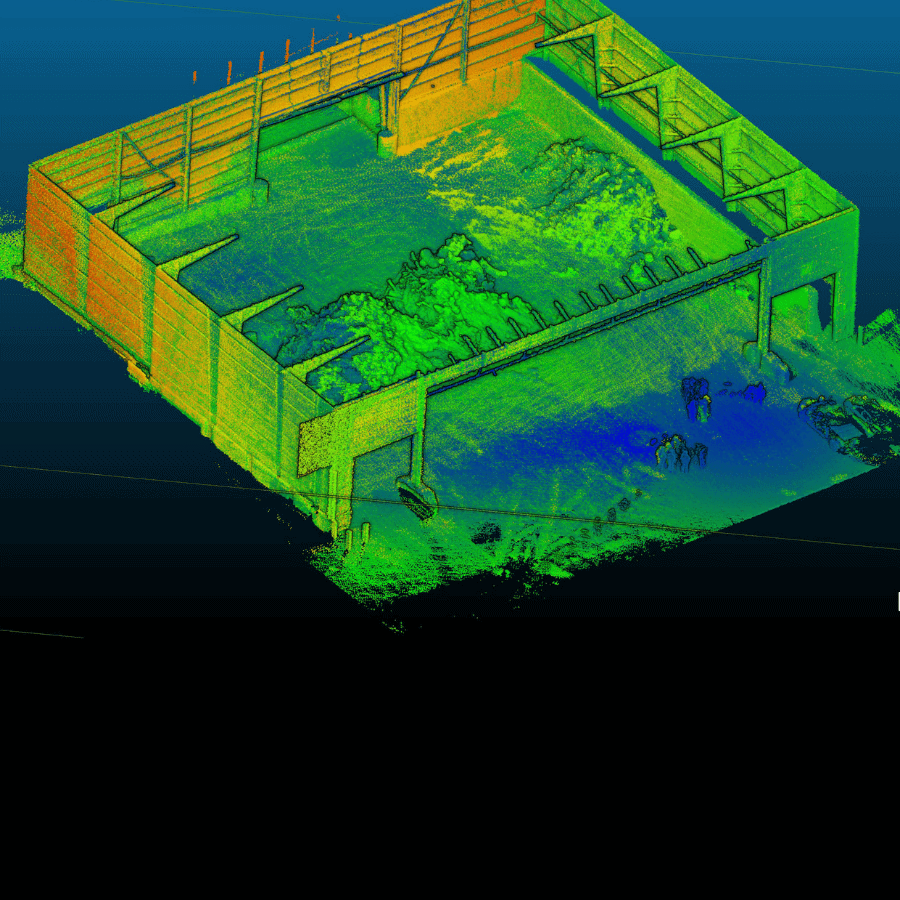

The waste is stored indoors while awaiting processing, and it falls under the purview of New York State’s complex Part 360 Solid Waste requirements. Solid waste management facilities (SWMF) need a clear understanding of the waste volume, how it is piled, how the piles are spaced, how high the heaps are, and its proximity to structures to ensure compliance.

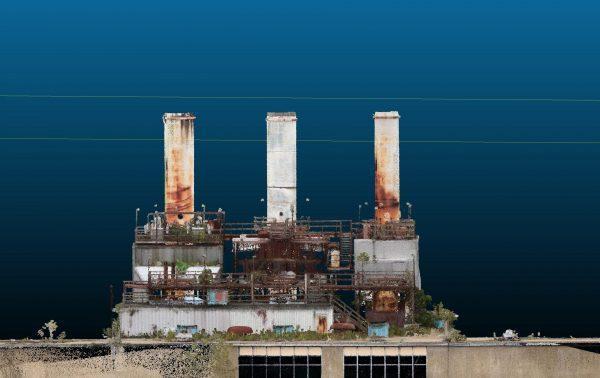

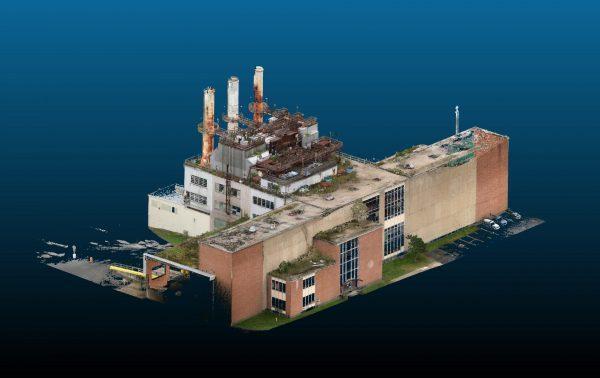

Recently, an SWMF based on Long Island, NY, enlisted Walden Environmental Engineering to assist in securing this understanding. Walden Environmental Engineering is a full-service environmental consulting firm that takes a collaborative approach to develop cost-effective, compliant solutions to their client’s challenges. To capture the data, Walden turned to trusted partner Harkin Aerial, a drone service provider with experienced drone pilot Scott Harrigan in the lead.

Capturing data like this can be challenging, explains Scott Harrigan from Harkin. The low light conditions of the indoor space meant drone or DSLR photogrammetry would not perform well.

“We would not be able to make quality models from the poor ambient lighting,” says Scott.

To use a tripod for laser scanning would require a very tall tripod to scan the top of the piles and setting up and breaking down of the scanner over and over to capture the entire area.

“That would have easily taken us an entire day to do, which is not efficient or cost-effective for the requested deliverables.”

So Scott took advantage of Hovermap’s ability to fly in GPS-denied environments, and collision avoidance and autonomous flight technologies to capture a top-down view of the piles with Hovermap mounted to a DJI M300 drone.

“In a matter of 15 minutes, we were able to capture a LiDAR scan of the entire warehouse structure, including every single interior pile,” says Scott. “And it only required one set of drone batteries.”

Scott then passed the data to Walden, who prepared a site plan containing the data required, helping the SWMF comply with their New York state Part 360 regulations.

Walden and Harkin have worked together on other projects to improve efficiencies and solve difficult problems. Learn more about them in the case study.