-

Faster, Safer Routine Bridge Inspection

Achieve greater visibility to pinpoint maintenance efforts

-

Conduct routine bridge inspection faster and more safely, without the need for GPS

Bridge inspection plays a critical role in maintaining infrastructure safety and longevity. In the U.S. alone, over 40% of bridges are over 50 years old, and more than 46,000 are considered structurally deficient, requiring urgent repair to avoid potential failure. This aging infrastructure threatens public safety, disrupts transportation, and incurs costly repairs and economic consequences, with risks extending to loss of life. Early detection of wear and damage through regular inspections is essential to prevent catastrophic outcomes. However, traditional bridge inspection methods are often expensive, slow, and face accessibility challenges, limiting their effectiveness.

Emesent’s Hovermap solution sets a new standard for safety, efficiency, and accuracy in bridge inspection. By eliminating reliance on GPS, offering superior image quality, and providing advanced 3D mapping, Hovermap ensures thorough inspections in even the most challenging environments.

The need for safer, more efficient bridge inspection

Conventional bridge inspections involve labor-intensive, costly, and often dangerous methods. Snooper trucks require lane closures, impacting traffic while crews manually inspect structures from elevated baskets. Other approaches—such as using barges, scaffolding, or abseiling—are hazardous, requiring work at height, and risking the safety of personnel.

Drones have recently transformed bridge inspections by reducing costs and time. However, most drones rely on GPS for stability, a challenge when satellite signals are weak, such as beneath bridge decks. This GPS limitation forces operators to use stand-off distances, which compromises image quality and can result in undetected defects. Smaller drones, while better suited for GPS-denied areas, often carry low-resolution cameras that don’t capture the detail needed for thorough maintenance decisions.

-

The Emesent Solution

Emesent’s cutting-edge combination of the Hovermap GPS-denied autonomy system and DJI’s M350 drone offers a breakthrough in bridge inspection. This solution enables inspections that are significantly faster and 40% more cost-effective than traditional methods, while also drastically reducing safety risks.

Hovermap’s Pilot Assist Mode leverages advanced LiDAR technology for precise positioning, eliminating the need for GPS. This allows the drone to safely operate close to bridge decks, capturing high-quality imagery even in low-light conditions. The system uses purpose-built cameras like the Zenmuse H20T to deliver crystal-clear images, and its stability ensures no defects are missed.

After the drone captures data, Emesent’s Aura software processes it into a highly accurate, 3D digital replica of the bridge. Inspectors can review colorized point clouds and 360-degree images that are georeferenced within the model, making it easy to identify and locate defects for future repairs.

With faster, safer, and more cost-effective inspections, Hovermap empowers bridge inspectors to make timely, informed decisions. Revolutionize your bridge inspections by exploring how Hovermap can transform your approach to infrastructure maintenance.

-

High quality imagery

Leverage purpose-built inspection cameras to capture detailed, actionable images

-

No GPS needed

Stable operation in GPS-denied locations beneath bridge decks

-

Faster, more frequent inspections

Capture detailed 3D data significantly faster than traditional methods, allowing more frequent and cost-effective monitoring

-

Safer operations

Inspections conducted remotely to reduce the need for personnel to work at dangerous heights

-

Complete data

Hovermap’s LiDAR-based positioning system allows users to capture high-quality images up close, so they never miss a defect

-

Efficient defect identification

Easily track changes and deterioration over time by comparing previous inspection data

-

-

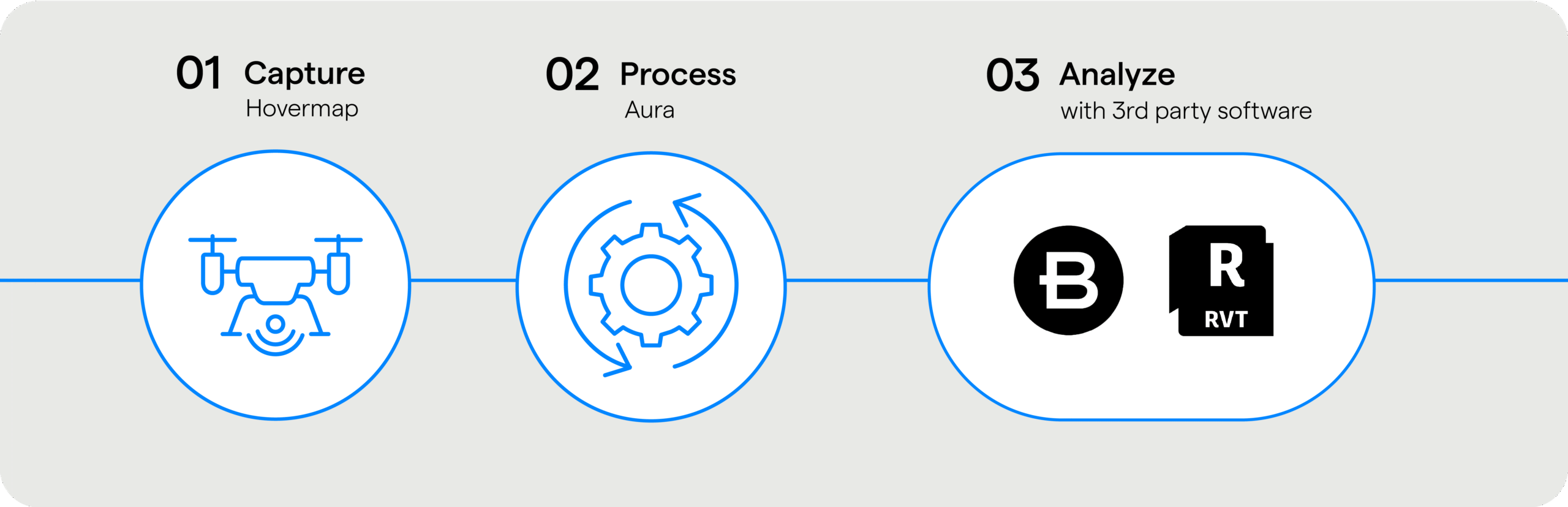

Operational workflow

- Deploy Hovermap autonomously on a drone or use pilot assist, with option to add a top mounted gimbal camera.

- Process, automatically georeference your dataset in Aura with RTK or GCPs, merge, clean and prepare. Import photosphere’s into Aura.

- Export to 3rd party tools – Bentley, Revit – for further analysis.

-

Revolutionize your bridge inspections

A new standard for safety, efficiency, and accuracy with Hovermap

-

Case study

Osprey Integrity Speeds up Natural Disaster Recovery with Fast, Accurate Data Capture

Historically, scanning a damaged bridge would be carried out manually by field personnel using terrestrial scanners and taking notes and photographs, or by using aerial photogrammetry. This can take hours.

But Osprey Integrity have reduced bridge data capture time by up to 65%. Find out how in this case study.

-

Want to see more?

Enquire now