-

Stockpile Measurement

Accurately measure stockpile volumes without the guesswork

-

Rapid data capture for accurate measurement of stockpile volumes over large areas

Accurate stockpile measurement is crucial for mining operations to manage inventory, track production, and ensure operational efficiency. While widely used across the industry, traditional stockpile survey tools can waste valuable time, delay production decisions and lead to inefficiencies in equipment allocation. For mining companies aiming to maximize profits and safety while reducing operational costs, adopting precise and efficient stockpile measurement methods is paramount.

Mining companies use various methods to measure stockpile volumes, each with its advantages and challenges.

- Total station surveys – While accurate, this method is time-consuming and labor-intensive, making it impractical for large stockpiles. In addition, while each individual point can be very accurate, without the correct density of points, the created model may not be a good representation of reality – leading to inaccurate volumes.

- GPS surveys – Although quicker than total stations, this method is still time consuming to achieve the point density required and also suffers from reduced accuracy in areas with poor GPS reception or signal interference, leading to potential measurement errors. This method of capture may also expose surveyors to safety hazards like rockfalls and ankle injuries if they need to climb the stockpile for a pick-up.

- Drone photogrammetry – While faster and safer, drone surveys can struggle in poor weather or over reflective surfaces, compromising data accuracy. Most drones also require GPS to fly reliably, making this method a poor choice for indoor stockpiles.

- Terrestrial LiDAR – While highly precise, this method is costly and inefficient for surveying large stockpile areas, as each scan requires the vehicle to be stationary for each scan. Indoor scans can be even more time-consuming,with multiple scans needed to attain full coverage, leading to delays and potentially interrupting production.

-

The Emesent Solution

Hovermap’s SLAM LiDAR technology overcomes the limitations of traditional stockpile survey methods. Unlike stationary terrestrial LiDAR systems, Hovermap can be mounted on drones, vehicles, or even used as a handheld device, continuously capturing data as it moves. With the ability to generate 1.9 million data points per second, Hovermap creates highly detailed 3D models of stockpiles faster than any other method.

Hovermap’s versatility supports multiple deployment options, including:

Drone integration: Mounted on a DJI M350 drone, Hovermap captures vast stockpile areas quickly and safely. Its advanced collision avoidance technology enables safe flight indoors and around structures, eliminating the need for manual data collection at stockpile peaks.

Vehicle RTK solution: For larger surface areas, Hovermap can be mounted on a vehicle for continuous scanning with automatic real-time kinematic (RTK) georeferencing & correction. This solution eliminates the need for ground control points, saving time and minimizing disruption to operations.

Automation with Boston Dynamics Spot: For fully automated small indoor stockpile surveys, Hovermap integrates seamlessly with the Spot robot. Using Spot’s mission planning software, operators can remotely execute high-precision scans without ever leaving the office. Spot autonomously traverses the floor around indoor stockpiles, capturing data continuously before returning to its charging station.

-

Faster workflows

Capture large areas in one continuous driving scan, saving time & reducing impact on production.

-

Survey-grade results

Automatically optimizes accuracy and corrects drift by seamlessly leveraging a combination of SLAM and RTK.

-

Reduced manual labor

Minimal set-up time and no need for stationary scans

-

Simpler scanning

For streamlined pick-ups, vehicle, backpack and handheld scans can be performed with minimal training.

-

High-definition capture

With 300-meter range & 1.9 million points per second, Hovermap delivers incredible data resolution over large areas.

-

Flexible deployment options

The versatility to deploy Hovermap in multiple ways to meet the demands of the environment.

-

-

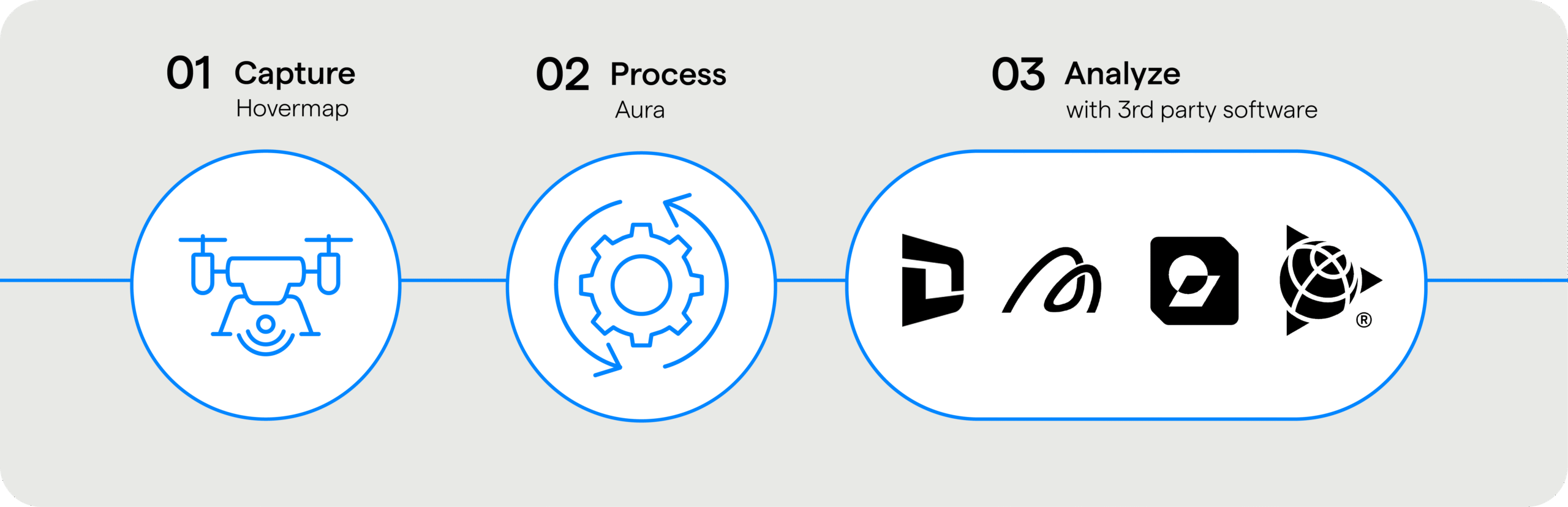

Operational workflow

- Deploy Hovermap on a drone, vehicle or handheld depending on stockpile size and environment.

- Process and automatically georeference your dataset in Aura.

- Easily export into 3rd party tools for volume calculations: Deswik, Maptek, Micromine, Trimble Business Center.

-

Maximize mine profitability

Rapid scanning for accurate measurement and reconciliation of mine production and stockpile volumes over large areas

-

Applications

-

Want to see more?

Enquire now