-

Infrastructure As-Built and Progress Monitoring

Accelerate infrastructure and construction projects with rapid, precise 3D as-builts

-

Efficient, accurate data capture throughout the construction lifecycle

Monitoring construction progress for infrastructure and construction projects is essential for early detection of potential issues that can delay timelines and add cost. Yet tracking real-time progress can be challenging, potentially leading to unforeseen delays and complications. Equally important is capturing as-builts, which provide an accurate record of the final construction, bridging the gap between design and reality, and serving as a reliable reference for future planning, compliance, and safety. However, these too can be challenging due the complexities of capturing accurate data, often resulting in incomplete documentation.

To meet the demands of modern infrastructure and construction projects more adaptable and integrated technology solutions are needed.

The challenge of complex construction environments

Existing data capture technologies for documenting the lifecycle across infrastructure and construction projects face significant challenges that impact the accuracy, efficiency, and completeness of the documentation process. Traditional methods, such as manual surveys and 2D drawings, lack the precision required for complex projects, leading to inaccuracies and incomplete as-builts.

While Terrestrial Laser Scanners (TLS) deliver high precision and accuracy, this approach can be time-consuming, particularly for large or intricate sites where construction moves quickly. Significant pre-planning is required, traffic may need diverting which is extremely expensive, and equipment must be set up and relocated multiple times – extending project timelines and delaying the availability of critical information. Additionally, difficulty capturing data in hard-to-reach or hazardous areas, such as high elevations or confined spaces, can result in gaps in the final documentation or substantially increase the time taken to create a design-ready deliverable. Furthermore, TLS operation requires the skills of an experienced surveyor creating a dependency on their availability.

-

The Emesent Solution

Emesent Hovermap combines accuracy with speed, enabling rapid data capture for delivery of detailed 3D data for construction progress monitoring or as-built documentation – in a fraction of the time of traditional methods and without the need for significant training. Leveraging advanced SLAM algorithms and continuous scanning capabilities, Hovermap offers an ideal solution for the demands of infrastructure and construction projects.

Delivering multi-faceted data capture capabilities in a single device, Hovermap offers versatile deployment options. Users can fly, drive, or walk the area depending on the environment, with options to mount it on either the DJI M350 or Freefly Astro drone for fast aerial capture, attach it to a vehicle for rapid large area coverage, or deploy it on a backpack for access to hard-to-reach areas. This versatility minimizes disruptions and area shutdowns while ensuring the best capture method is employed for the environment. The scans can be easily merged to create a single final output.

Additionally, Hovermap’s RTK integration automates georeferencing and drift-correction enabling the delivery of fast, accurate and precise scans – without the need to lay out and georeference ground control points. Intelligently leveraging both RTK and SLAM to optimize results, RTK ensures the most reliable, robust point cloud and delivers seamlessly georeferenced outdoor to indoor scanning without GCPs. Combine with the 360 colorization kit for Hovermap to add a new level of reality and extract 360 degree images for additional context.

The data captured is easily exported into BIM tools like Revit for continuous updates and maintenance throughout the project lifecycle.

-

Rapid data capture

Data capture at least 10x faster than traditional methods allows for regular scanning for comparison with the design

-

Faster workflows

Automated target detection and georeferencing means there is no need to touch each control point – allowing for continuous scanning and non stop image capture

-

Accurate results

Capture precise 3D spatial data and intricate structural detail including walls, ceilings, floors, MEP and HVAC systems

-

Ease of use

A user can capture accurate data in minutes without the need for significant training

-

Versatile deployment

Multi-platform deployment options ensure the best data capture method for the environment from large environments to hard to access areas

-

Increased competitiveness

Faster data capture allows completion of more jobs in a shorter time — good for your business, good for your client

-

-

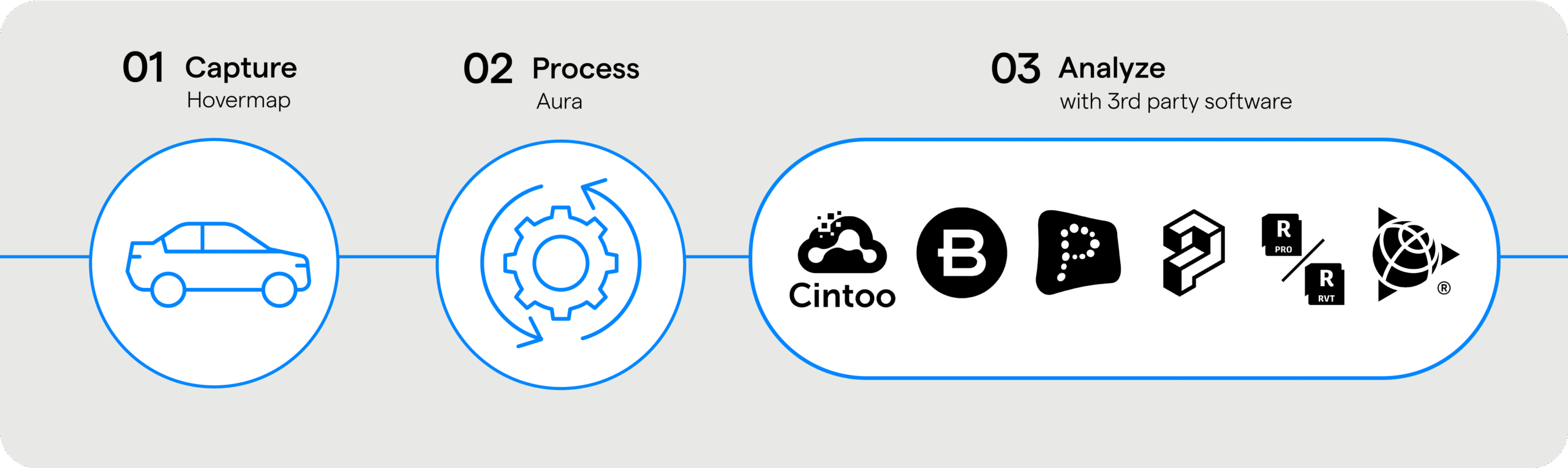

Operational workflow

- Deploy Hovermap on a vehicle, drone, or backpack.

- Process, automatically georeference your dataset in Aura with RTK or GCPs, merge, clean and prepare.

- Easily import into 3rd party tools – Cintoo, Bentley, Pointerra, Prevu 3D, Recap/Revit, Trimble Business Centre – to monitor, track progress and compare actual to design.

-

Rapid, accurate 3D data capture for as-built modeling

Improve competitiveness with rapid, accurate and continuous data capture of complex environments.

-

Case study

Brierley Associates Speeds up road tunnel inspection

Brierley Associates sought a solution to tunnel inspection that would reduce the disruption to traffic while keeping the inspection team safe.

Instead of using the typical tunnel inspection method of having a field inspector walking the length taking notes and photographs, and requiring the road’s closure for at least six hours, Brierley Associates inspected a two-lane, 125.2 m (410.8 ft) with Hovermap in a one-hour inspection.

-

Want to see more?

Enquire Now