-

Fully Autonomous Stope Mapping and Rapid Visualization

Eliminate uncertainty to optimize mine planning and production

-

Map hard to access underground excavations – efficiently and accurately

Accurate stope geometry and volume assessments are critical for optimizing production and ensuring structural integrity in underground mining. However, limited access, safety risks, and data collection challenges often stand in the way.

Emesent’s Stope Reconciliation solutions overcome these obstacles with safe, accurate and fully autonomous data capture, delivering complete insights into inaccessible voids. Operators can verify design conformity, assess ore dilution, and improve blasting efficiency—maximizing profitability while keeping personnel and equipment safe.

The challenges faced

A Cavity Monitoring System (CMS) is a common tool for assessing underground voids, but its bulky equipment, manual handling, and significant setup and scan time pose challenges. More critically, personnel must remain close to the stope opening, exposing them to risk. Plus, the requirement for stationary scanning can lead to shadowing, leaving gaps in the data.

Drones offer a safer and more comprehensive alternative—provided the stope opening is wide enough. However, many drone-based solutions face limitations BVLOS (Beyond Visual Line of Sight) and require additional communications infrastructure, restricting capabilities. In the worst case, a loss of communication could mean losing the drone entirely.

-

The Emesent Solution

Emesent’s stope reconciliation solutions allow geotechnical engineers and surveyors to efficiently and accurately map hard to access underground excavations to ensure compliance to design — quickly and safely, whilst minimizing impact to production. Hovermap’s unmatched versatility sets it apart, while offering multiple deployment options that maximize ROI from a single device.

Drone mounted capture

Hovermap’s fully autonomous navigation integrated with next-generation drone platforms delivers fast, reliable data capture in the most challenging environments— without the need for GPS.

Powered by Emesent Cortex, featuring AI powered autonomy, Hovermap enables autonomous flight beyond visual line of sight and communications range, making it ideal for mapping hard-to-reach or previously inaccessible areas. Whether you’re dealing with tight spaces, heavy dust, or high humidity, Hovermap’s industry-leading SLAM technology ensures accurate, confident mapping every time.

Entire missions—from takeoff to landing—can be executed using just a tablet, keeping operators at a safe distance. Live point cloud streaming via the Commander app provides real-time visibility, while onboard processing delivers instant insights, as well as optimizing the data for rapid network transfer and ease of manipulation with third-party analysis tools.

Hovermap also offers three flexible operating modes, so you can tailor the level of autonomy to your needs—from Pilot Assist, which blends human control with automated safeguards, to fully autonomous missions for maximum efficiency.

LHD mounted capture

See further with Hovermap LHD. Easily mounted to an LHD via a purpose built mount, Hovermap transmits data to the surface via the site network. This enables operators to remotely scan the working face and visualize results in near real time, providing context and enabling analysis while keeping personnel safe. With a 300-meter range and 360° field of view, Hovermap delivers a complete map of the stope, even in total darkness. Operators can identify loose rock, structural hazards, and rill angles in minutes. Its plug-and-play design means crews can perform accurate stope scans anytime, day or night, without the need for significant training.

Hovermap LHD puts an advanced 3D analysis tool in the hands of operators so they can make faster, better decisions as they go, while allowing safe and efficient LHD operation from the surface and removing personnel from potential harm. It can also be deployed on any other equipment or vehicle.

CMS boom mounted capture

Capture more detailed, accurate 3D data in less than half the time of traditional CMS in hard-to-access underground voids not suitable for a drone, such as very small openings. Attached to a CMS boom or pole, Hovermap captures a highly detailed and dense point cloud of a stope in just 1-2 minutes – allowing more accurate volume calculations and geotech structure mapping that improves mine engineering processes.

Unlike traditional CMS, which requires stationary operation, Hovermap can be moved during scanning, providing better coverage per scan with minimal shadowing.

-

Faster data acquisition

Longer flight time, extended range and greater field of view allows faster data acquisition over larger areas, improving efficiency, especially for large stopes and larger scale projects

-

Confident decision-making

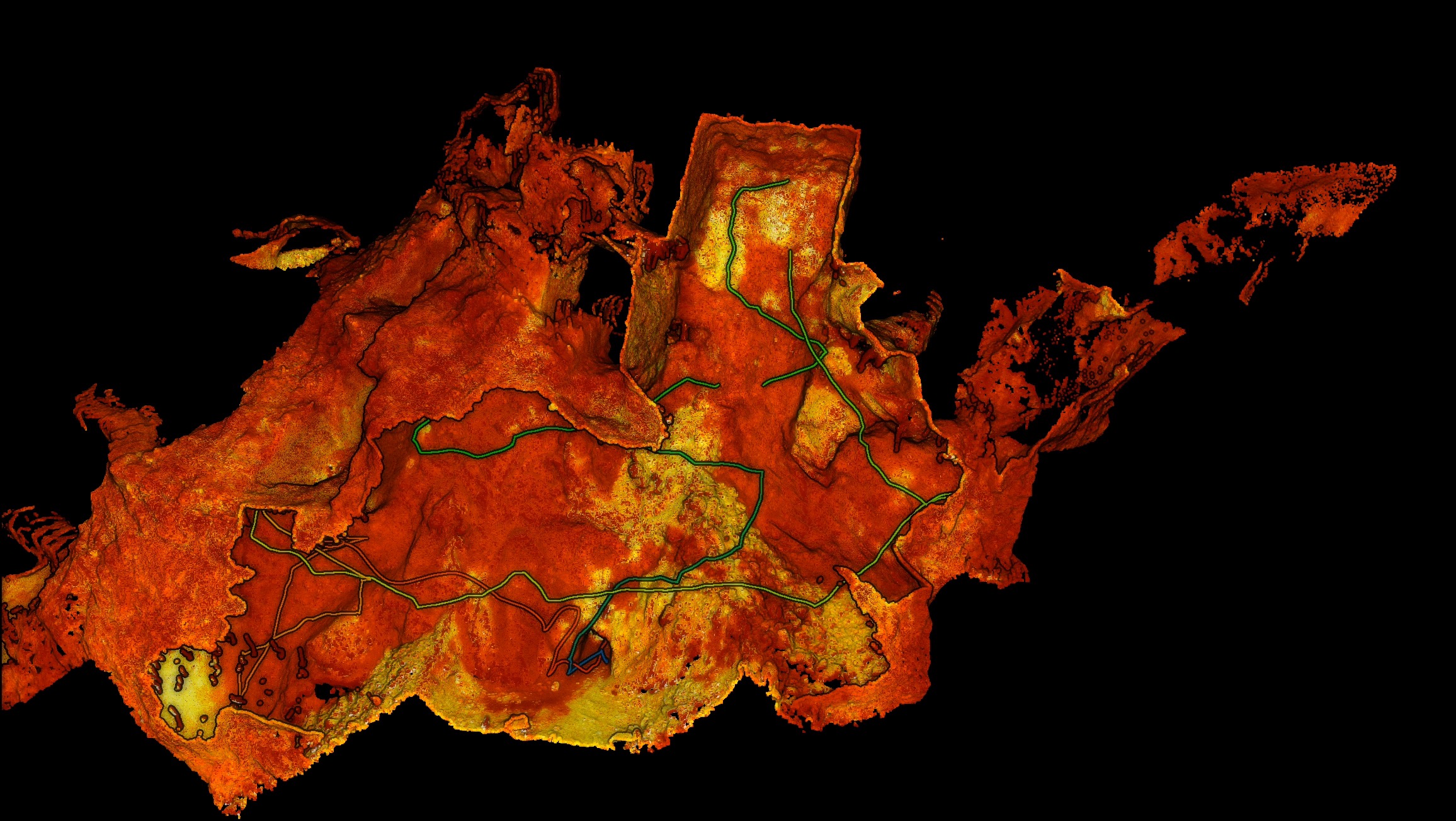

Eliminate guesswork with data capture of previously inaccessible areas and accurate, high density point clouds to confidently reconcile stope volumes

-

Full autonomy

With proven reliability in the most challenging environments, Emesent’s world leading SLAM delivers advanced autonomous navigation and collision avoidance without the need for GPS

-

Improved efficiency

Automated georeferencing saves time and improves accuracy by eliminating manual and error prone processes

-

Greater ROI

When more than a single scanning technique is needed, the versatility of Hovermap allows multi-platform deployment throughout the mine – drone, vehicle, handheld, backpack, pole – providing greater ROI from a single device

-

Safer operations

Autonomous and remote data collection keeps personnel from harm, while providing reliable, detailed data capture in hazardous environments

-

-

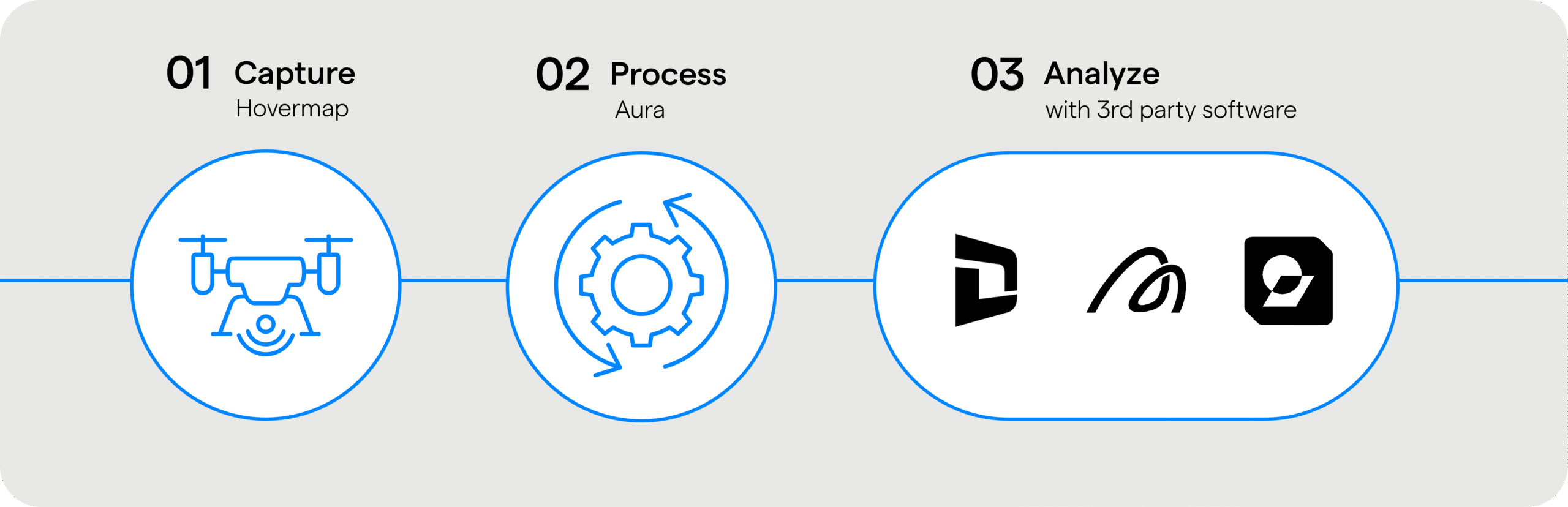

Operational workflow

- Deploy Hovermap on a drone, LHD or CMS.

- Process and automatically georeference your dataset in Aura.

- Easily export into 3rd party tools – Deskwik, Maptek, or Micromine – to compare the result with the design, determine overbreak/underbreak, or estimate dilution and ore losses using block models.

-

Testimonial

“A boom scan could never provide us with the data that Hovermap is able to collect during our monthly reconciliation scanning program. Having the correct visualization makes a huge difference to volumes and with Hovermap you get amazing volume straight off the bat.

Our geologists were very pleased with the data we sent through to them.”

Martin Le GrangeBarrick Survey Manager, Bulyanhulu

-

Rapid capture of detailed geotechnical data to optimize mine design

Fast, safe 3D data capture, whilst minimizing impact to production

-

Applications

-

Case study

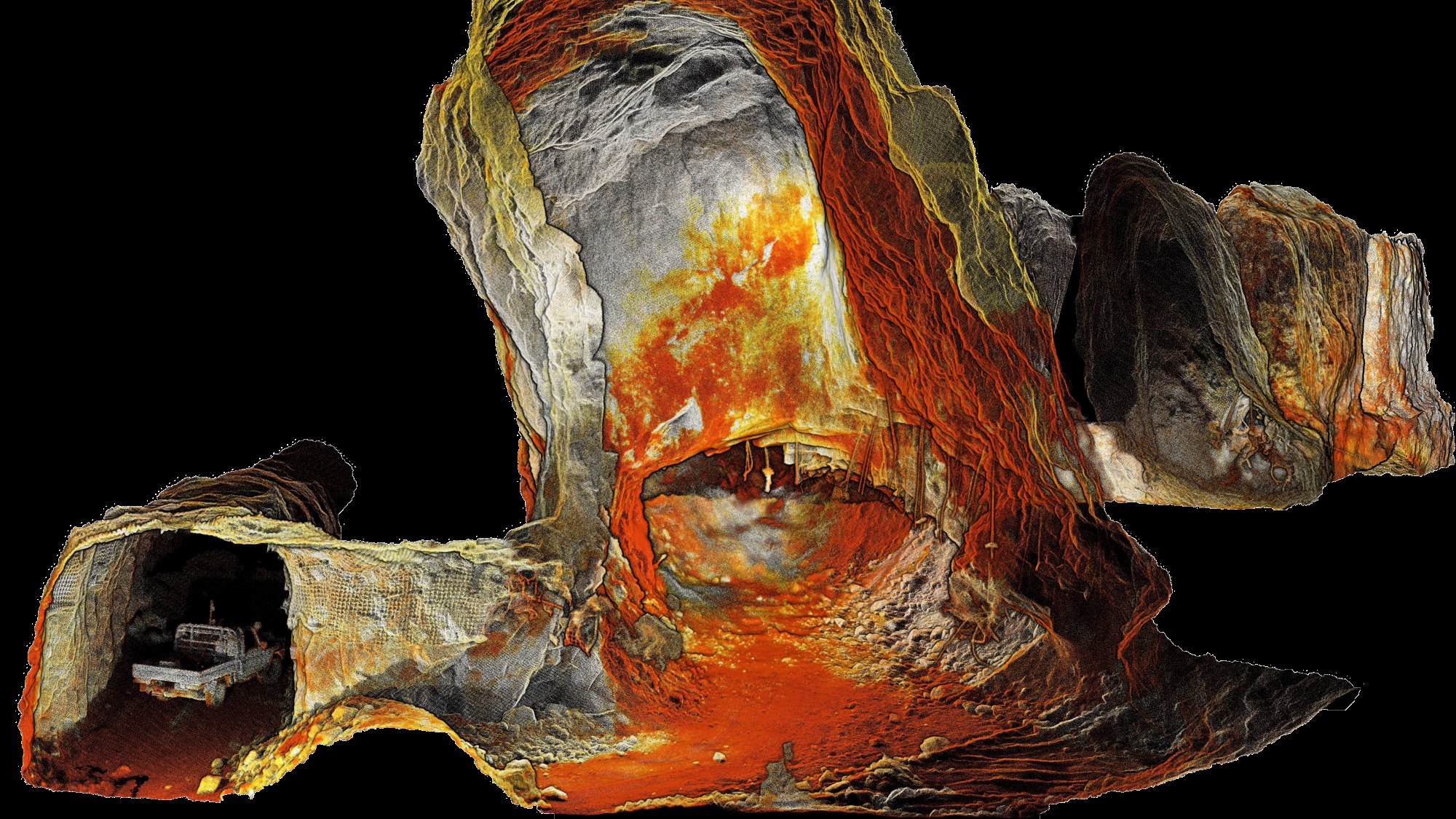

Mapping the Carrapateena mega cave

When a 5m diameter hole appeared at the surface of one of the largest copper reserves in the world, regular scanning became critical in order to ensure both the safety of personnel and the stability of mine operations.

Learn how Emesent Hovermap conquered the inaccessible.

-

Related Resources

-

Want to see more?

Enquire now