Updating As-Built Asset Model of a Geothermal Steam Turbine in Under One Hour Onsite

As is frequent with older industrial assets, as-built drawings and schematics of the original assets and engineering are often incomplete or outdated. There may have been significant maintenance changes and equipment improvements, but the records of those changes are not available. As a result, it is often not clear what is the actual as-built condition of the assets and equipment that are operationally used.

Gathering and verifying this as-built documentation for maintenance and repairs can take Petamina engineers several months and multiple site visits. This is an expensive and time-consuming process that is almost always required before the actual maintenance work can begin.

Based in Jakarta, Halo is the largest commercial drone distribution and services company in Indonesia. It works with global technology leaders as an authorized distributor and service partner in Indonesia.

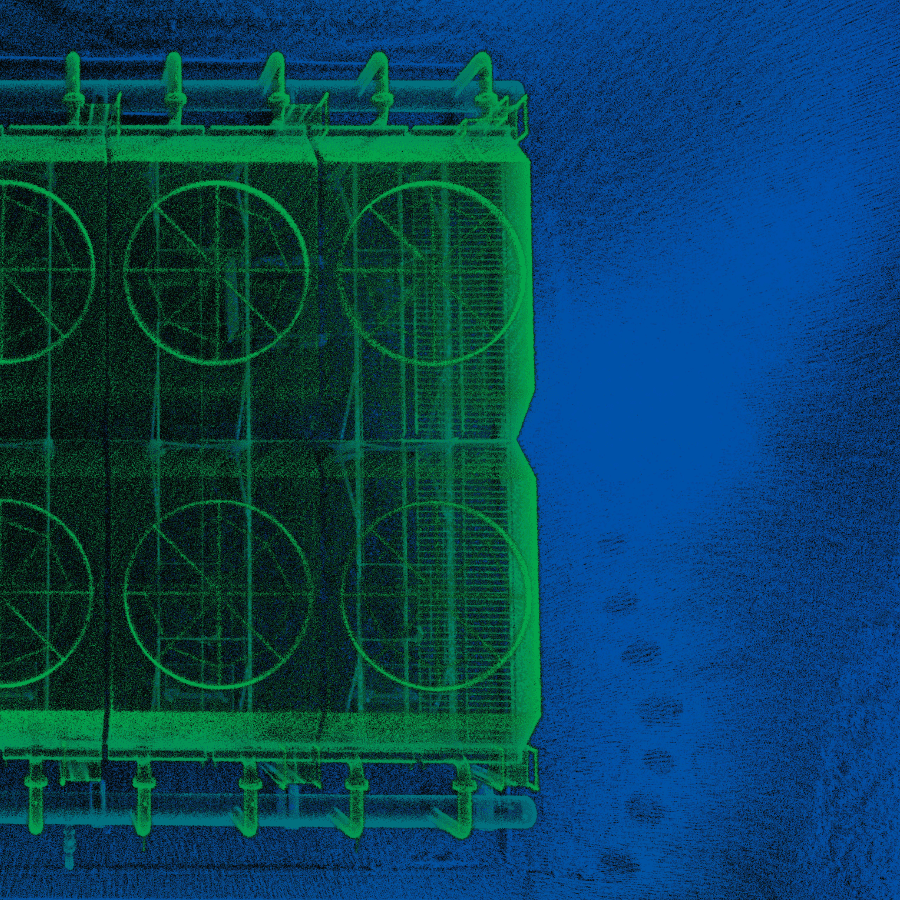

In just 30 minutes, Halo Robotics walked through the facility, scanning the turbine, generator, condenser, cooling tower, and pipework of the facility – producing a high resolution LiDAR point cloud.

Halo Robotics processed the data to produce a 3D model for Pertamina’s CAD systems with a very high level of accuracy and detail. The model updated the engineering as-built so Pertamina engineers could produce accurate up to date drawings and schematics for the plant assets.

“Pertamina was happy with the results of the scan, confirming it provided the required Level of Detail necessary for engineering-standard CAD modeling for maintenance operations,” said Eli Moselle, CEO of Halo Robotics.

“We demonstrated that by using SLAM-based LIDAR scanning technology, we can quickly and accurately scan a complex asset, like this geothermal turbine plant, without GPS; and that an as-built model could be updated quickly and in a much more cost-effective way. The applications are wide-ranging for operations and maintenance throughout the company’s significant portfolio of brownfield production assets.”

See another example of how Hovermap is used in the Oil & Gas industry in this case study of a compressor station.