Safely exploring 148 year old tunnels with LiDAR mapping

Using LiDAR mapping, Wingfield Scale and Measure have explored and captured inside train tunnels abandoned over 60 years ago to help prepare them for a new role.

In 1956 the last steam locomotive passed through the Wray and Sidling Tunnels in Rockhill Furnace, part of the 32-mile (51.5 km) coal rail line. Over 60 years later, the tunnels are being entered again, this time in preparation to bring tourists to Rockhill Furnace and the surrounding cities.

Bored in 1874, the tunnels were part of the East Broad Top Railroad, one of the earliest railroads in America to use the narrow-gauge line, allowing for the construction of sharper curves and lighter bridges due to the smaller rail. Now, the oldest surviving narrow-gauge railroad east of the Rocky Mountains, they are part of the ever-expanding rehabilitation program of the 27-mile (43.5 km) track, including the Wray and Sidling Tunnels.

The East Broad Top Railroad Foundation (EBT) is a nonprofit foundation dedicated to restoring and preserving the rail lines, six steam locomotives, a roundhouse, rail and engine manufacturing shops, and other passenger and freight cars. The focus now is rehabbing the Wray and Sidling Tunnels.

The first step in understanding the condition and best approach for rehabilitation is getting video and LiDAR data from inside the tunnel. This is challenging, as old and disused tunnels pose a safety risk with the possibility of collapse or settlement of ground. Before data collectors are permitted to enter the tunnel, an inspection and, if necessary, shoring of the support structure is required. This can cause lengthy delays and add to the costs of the rehabilitation project.

The team at Wingfield Scale and Measure, a measuring solutions company, was well aware of these concerns when they were commissioned to provide the EBT the data to begin rehabilitation planning for the tunnels. Knowing ground-based robots were unsuitable due to the unknown ground conditions, Wingfield chose to use Hovermap, mounted to a DJI M300 for data capture.

Left, Austin Brooks and Right, James Kenney with Wingfield Scale & Measure. Knowing the possible dangers in the decommissioned tunnel, the Wingfield team sent in a Hovermap-enabled drone to investigate its condition.

“Hovermap is one of the tools in our kit that sometimes stands on its own for the only way to safely capture data.”

James A. Kenney, Senior Engineer

– Wingfield Scale

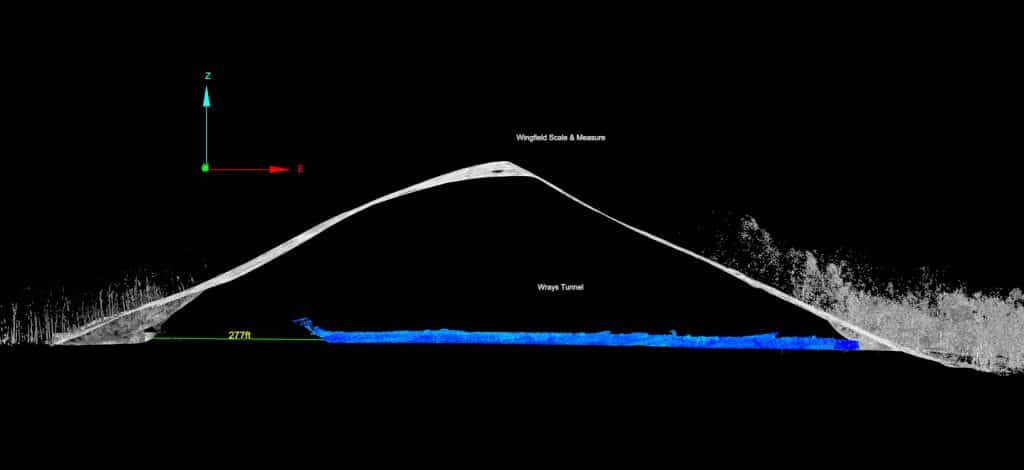

In spring 2022, the Wingfield team spent a day onsite to capture survey-grade GPS, airborne, and terrestrial LiDAR data from both the Wrays and Sliding Tunnels.

In spring 2022, the Wingfield team spent a day onsite to capture survey-grade GPS, airborne, and terrestrial LiDAR data from both the Wrays and Sliding Tunnels.

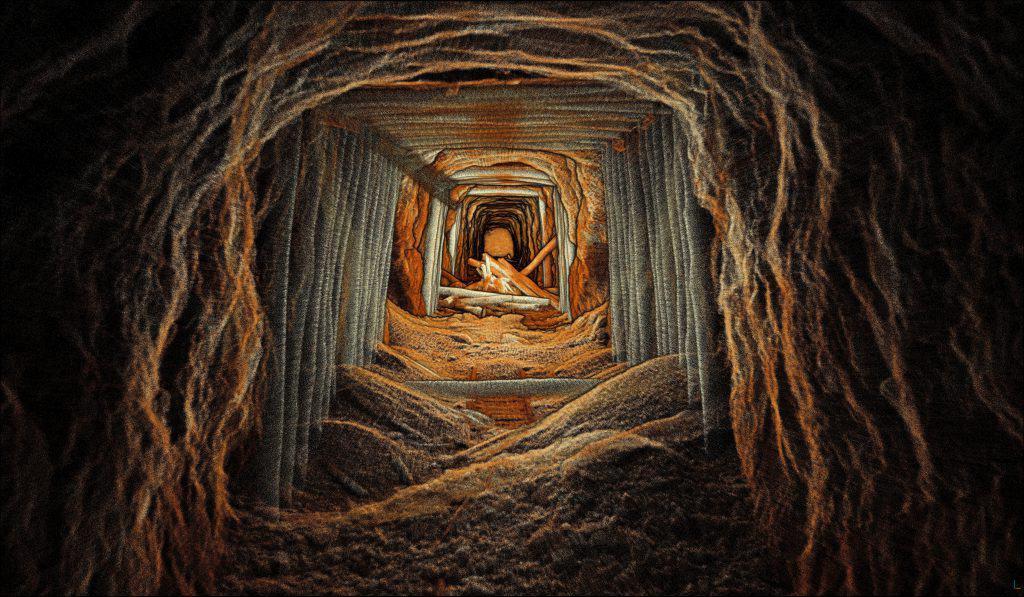

With the onboard camera of the M300 and Hovermap mounted below, they used Hovermap’s Pilot Assist Mode to navigate the tunnels, with the onboard camera providing the UAV first-person view video for visual inspection. Hovermap’s omnidirectional Collision Avoidance and GPS-denied flight capability, available in Pilot Assist Mode, act as a safety bubble around the drone, keeping both the equipment and the tunnel safe. At one stage during the tunnel exploration, the drone lost connection with the operator’s controls, and Hovermap engaged its communication loss protocol and began planning and executing a safe Return-to-Home – another measure to ensure the safety of the equipment and tunnel.

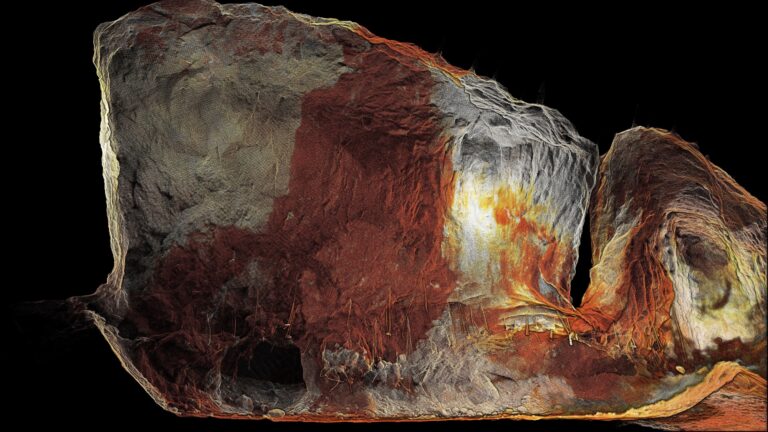

The LiDAR scan from within the 148 year old tunnel showed collapsed support timber sets, justifying the decision to send in a drone instead of personnel.

Sending in a drone was confirmed as the best course of action when the Wingfield team discovered, through the scan, that support timber sets had collapsed within the tunnel, which otherwise would have required shoring before personnel entry and would limit ground based autonomous vehicles.

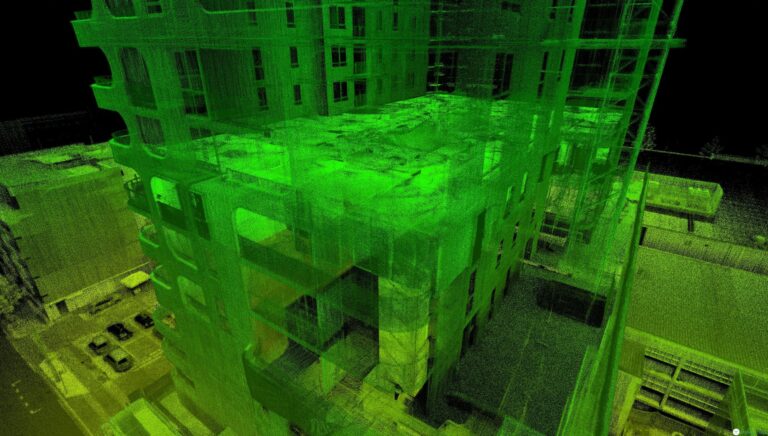

Back in the office, the Wingfield team took advantage of the Maptek Point Studio and Hovermap integration, as well as their own custom import workflows to facilitate the import and post processing of the Hovermap data. Maptek Point Studio was also used to combine all the LiDAR scans, as well as photogrammetry data using Wingfield’s proprietary workflows to produce a single dataset. Using Point Studio, the combined dataset was georeferenced with State Plane Coordinates, filtered, and quality control checks performed before the final deliverables were exported.

Along with the final deliverables from the dataset, videos and screen captures were provided to the EBT. This will be used by the rehabbing companies to better plan and scope the rehab project for the tunnels. Beginning with the planning of their safety requirements, this data will also be used to measure the material to be removed, as well as the amount of water ingress and the overall conditions of the tunnels. The accurate data will allow contractors to provide more accurate quotes to ensure they are on time and on budget.

The ability to rapidly map inside the tunnels with a drone-mounted Hovermap reduced Wingfield’s time in the field, a saving they passed along to EBT.

“Without the use of Hovermap, it would have not been possible to achieve the caliber of data collection on this project,” says James.

The final deliverable also provides EBT with a historical record of the condition of the tunnels at a known point in time – something that hasn’t been completed since the tunnels were first made in 1874.

The Wingfield team combined all the LiDAR scans and photogrammetry data using their proprietary workflows to produce a single dataset, providing EBT with an up to date and accurate account of the tunnel’s state.

“EBT (East Broad Top) Railroad is celebrating 150 years, and here we are now using the highest level of technology to refurbish the railroad. This is amazing, seeing the past come alive through the data gathered. The LiDAR mapping is incredible, and we had no idea how detailed it would be. This helps us document and better plan refurbishment while keeping a high level of safety.”

James Roslund, Director of Engineering

– East Broad Top Foundation Inc.