Maximize mine productivity and safety

See Hovermap autonomy in action

-

Map challenging and GPS-denied environments

Emesent pioneered the use of autonomous drones in underground stope mapping, ensuring a safer and more efficient mapping workflow at some of the biggest mines worldwide.

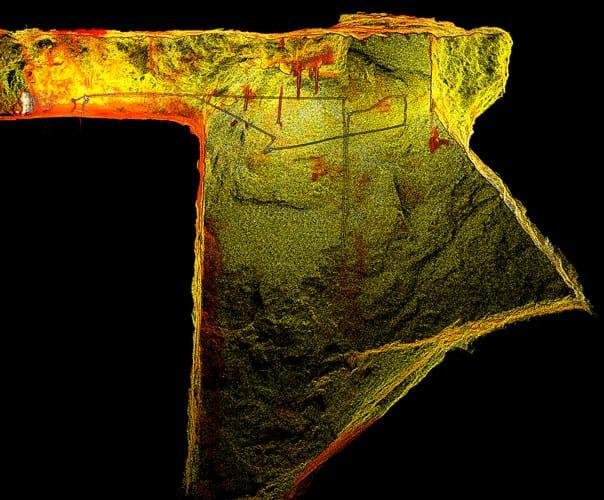

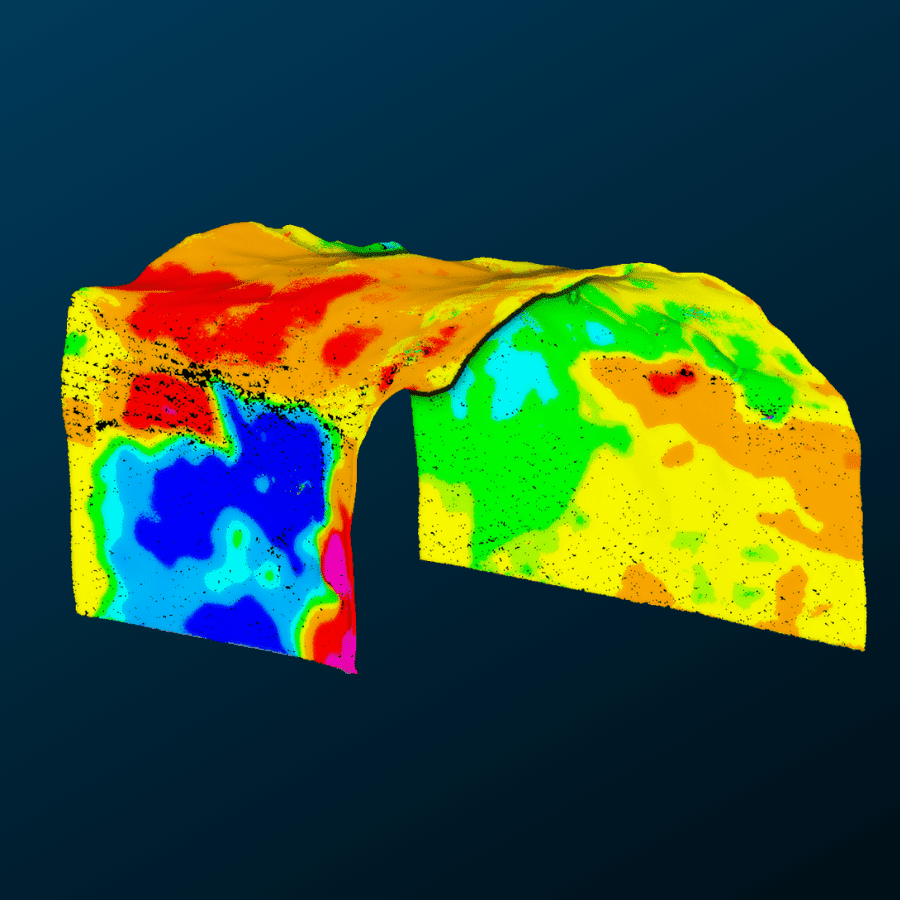

Offering a uniquely versatile mine mapping solution, Hovermap can be deployed on a drone to provide autonomous mapping in stopes and vertical shafts, convergence monitoring in drifts, evaluation of new blast designs, and an accurate, up-to-date picture of inaccessible areas. It can also be used as a vehicle-mounted scanner to capture drives or lowered down raises and orepasses in a cage.

-

Use Hovermap for

-

Accurate volumetrics

A quick Hovermap scan captures high resolution data to output high accuracy volumetrics for over/ under break calculations, volumetric reconciliations, material dilution and backfill paste scheduling.

-

Improved mine safety

Hovermap provides improved awareness of ground and structural conditions and better visibility of hazards for mitigation before they become a problem. For example, shadows in CMS scanning may hide an overhang at the edge of the stope that could be fatal.

-

Keep personnel safe

Remove personnel from hazardous areas by capturing high resolution point cloud data with a Hovermap-mounted drone, eliminating the need for risky capture methods like CMS or for personnel to go near a bund or drawpoint.

-

Improved compliance

The high resolution, shadowless data provided by Hovermap can assist with compliance with regulations like bund height and positioning, improving the safety of your mine

-

Enhanced efficiency

Surveyors using Hovermap are able to capture data of voids and drifts up to 75% faster than using previous methods. Hovermap’s remote autonomy capabilities allow surveyors to carry out scans quickly. Accurate, complete data allows for more confident planning, resulting in fewer production delays and reduced operating costs.

-

Access the inaccessible

Capture rich, 3D, shadowless images from previously inaccessible areas with Hovermap’s autonomous capabilities. Investigate old workings that may have been untouched for over a century for reopening quickly and safely.

-

Monitoring for deformation

The detail of Hovermap scans allows for a richer understanding of geological structures and to assist in identifying deformations. Hovermap scans can help identify and track joint sets and faults throughout the rock mass. Repeat scans of drifts, orepasses, and chutes make it easy to monitor for change and track deformation over time to assist with identifying potential fall-of-ground areas.

-

Above-ground scanning

The same unit used autonomously underground can be used above ground as a drone-mounted, vehicle-mounted, handheld, or backpack-mounted scanner. Use it to capture stockpile volumes or infrastructure for digital twin creation, condition monitoring, or rehabilitation planning.

-

-

See Hovermap autonomy in action

-

Award Winning Solution

-

Augment visibility in underground environments

-

Capture and visualize data for above-ground use cases

-

Explore real-life Hovermap applications

-

Clients using Hovermap

-

Testimonial

“The Hovermap has given us the flexibility to deploy the scanner further into the void to help us remove all of the shadows. We’ve got the true void volume.

The Hovermap improves mining efficiency in the way that we’re not holding up the production team as long. We’re just in and out really.

Changing to the Hovermap (from CMS) moves us to the next level of safety by taking us further away from the hazards.”

Senior SurveyorMount Isa Mines, Glencore

-

Why use Hovermap?

-

Explore beyond line of sight

When mounted to a drone, Hovermap’s Tap-to-Fly autonomy feature enables mapping in previously inaccessible areas beyond line of sight and communication range. The omnidirectional Collision Avoidance, Guided Exploration, and smart Return-to-Home functions ensure your Hovermap keeps a safe distance from assets and returns home safely with the valuable data it has collected.

-

Built for harsh conditions

The tough, weather sealed, IP65 rated unit is dust and water resistant, allowing you to map in severe environments. It can operate in temperatures from -10 to 45°C (14 to 113 °F) as well as high humidity, making it ideal for use in underground mines and other harsh environments.

-

Unique versatlility

The plug and play design and quick-release mechanism allow easy switching between modes. Use Hovermap as a handheld scanner; attached to a drone, vehicle, or pole; lowered in a cage; or mounted to a backpack to easily collect data anywhere. The compact, lightweight design makes it easy to carry and provides longer flight time.

-

Automated GCP workflow

Georeferencing in underground mines uses standard prisms and spigots that require specialized mounting adaptors. Emesent has developed mining specific GCP’s and GCP adaptors that meet these specialised requirements. GCP’s are automatically detected during scanning, improving accuracy and eliminating the need for manual georeferencing of the point cloud post processing.

-

Improved decision making

Mining decision-making is improved with autonomous data capture for volumetrics, over/under break, deformation monitoring, and geotechnical stability monitoring.

Hovermap’s versatility provides autonomous mapping in challenging, inaccessible areas, while the rotating LiDAR provides an omnidirectional field of view, ensuring 3D data is collected in all directions for complete, shadowless point clouds.

-

Reliable data

With a combination of world leading LiDAR mapping and drone autonomy, Hovermap produces reliable, accurate data which integrates seamlessly with existing workflows to enable new analytical insights.

-

-

Hovermap versatility

-

Hovermap-Spot Autonomy

Hovermap’s unique versatility means the same unit can be used on Spot or a drone for autonomous mapping.

Spot can be stationed underground and sent missions from the surface to collect data for change detection, convergence monitoring, post-blast evaluation, remote ground support inspections, and more.

Applications for Hovermap-Spot to replace personnel in hazardous first response situations are also being developed. Remote and autonomous routine mapping with Hovermap-Spot is currently under development.

-

Vehicle-Mounted

Use the suction cup or magnetic vehicle mount to quickly and easily attach Hovermap to various vehicles (including steel, aluminum, and plastic). From boggers to transport vehicles, these mounts will allow you to capture data anywhere your vehicles go.

-

Drone-Mounted

Keep personnel away from brows, stope edges, confined spaces, or heights. Fly a Hovermap-enabled drone beyond line of sight and capture critical data to assess the stability of geological features and improve decision-making in mine safety and design.

-

Equipment-Mounted

Use the suction cup or magnetic vehicle mount to quickly and easily attach Hovermap to various vehicles (including steel, aluminum, and plastic). On Load Haul Dump (LHD), Scooptrams, Boggers, Dozers, Roof Bolters or even elevator roofs, these mounts will enable you to capture data anywhere your vehicles go.

-

Cable Application

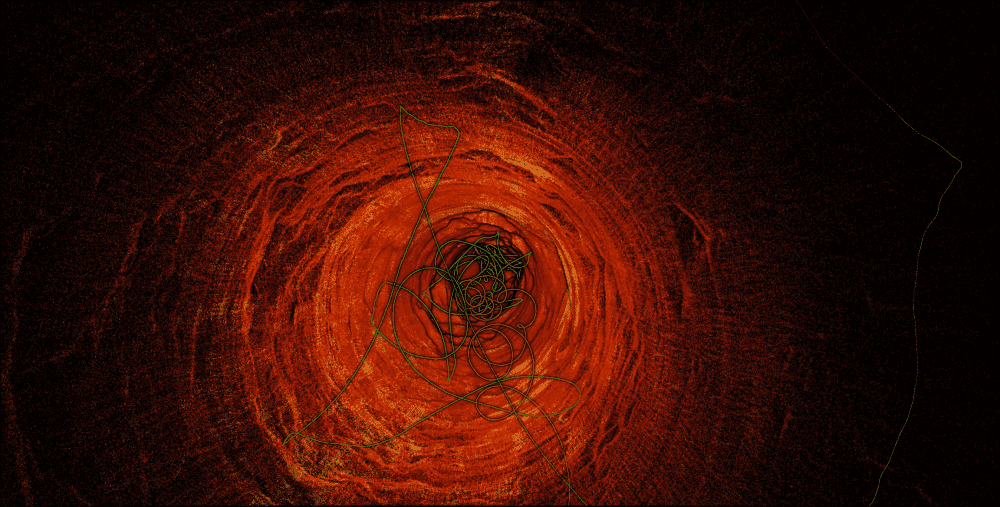

The Hovermap protective cage provides hard wearing protection that is specially designed to slide smoothly, avoid snags and deliver great scans.

In this raisebore shaft with a 5 m diameter and 500 m depth, Hovermap was lowered down with a cable to collect the valuable data.

-

-

Integrated workflows

-

Deswik

A semi-automated workflow has been created to import Hovermap data into Deswik’s design and solids modeling platform, Deswik.CAD. This workflow enables users to translate the Hovermap data within minutes, creating usable surfaces, solids, and point clouds for as-built surveys, volume reporting, and design updates.

-

Maptek

This integration provides an easy workflow between Hovermap data and the Maptek PointModeller software, which is easily able to handle the high levels of data produced by Hovermap.

-