Trafikverket and AMKVO Bring Underground Data to the Surface

Autonomous mapping in vertical shafts makes for fast, efficient digitalization

Good mapping data is essential for underground infrastructure work. Inaccurate or incomplete mapping data sources can increase the risks to personnel, equipment and infrastructure in an already high-risk environment. But vertical infrastructure can be particularly difficult to map – the width of a space might make it inaccessible to workers, while longer shafts can be hazardous to both people and equipment.

On top of this, traditional ground-based scanning methods such as tripod-mounted laser scanners are logistically limited in what they can capture, resulting in low-quality data. The good news is that using autonomous scanners in vertical shafts can help bring high-quality data into the light.

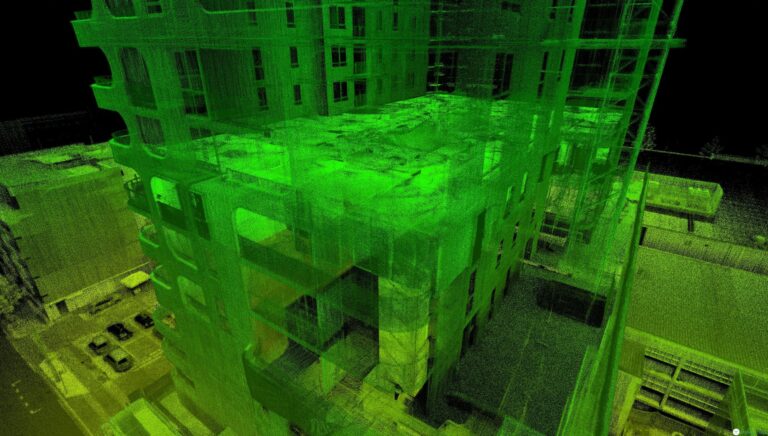

In 2019 Sweden’s traffic authority, Trafikverket, needed to map the vertical ventilation shafts in a new underground road tunnel development near Stockholm. They wanted to monitor the shafts to ensure safe and efficient operations, and identify water inflow to see where the rock mass might be at risk of deterioration.

Trafikverket engaged our European partners, remote sensing specialists AMKVO, to capture the data using Hovermap, with Emesent Technical Evangelist Jeremy Sofonia, PhD, providing additional expertise on the project.

Hovermap can be used to scan vertical shafts by lowering it in a cage or mounting it to a compatible drone. In this case, it was mounted to a DJI M210 for two beyond line of site flights – one from the surface, and one below ground. Both scans were completed in under two hours, and were then merged in the Emesent Processing Software to create the complete point cloud.

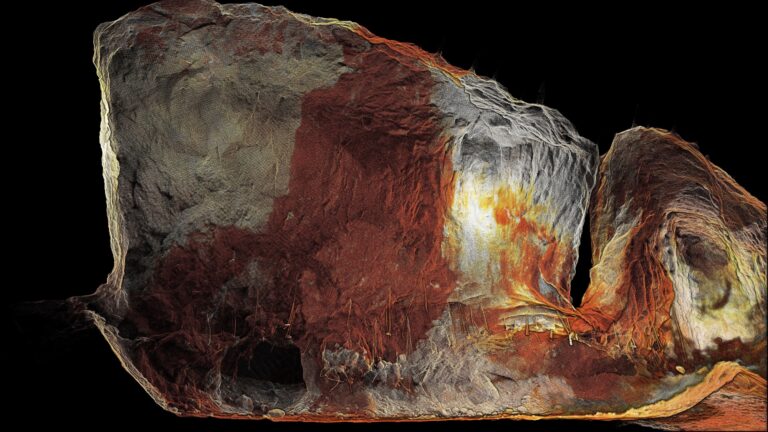

The time saved in data capture and processing meant that the point cloud data was available a lot sooner than it would have been using traditional surveying methods.. Trafiverket were then able analyze the point cloud in CloudCompare to visualize airflow modeling, seismic monitoring, water ingress and a range of other factors.

The ease of scanning with Hovermap means that comparison scans can be regularly taken throughout the lifecycle of any asset, such as during construction, operation, or once the asset has been decommissioned. This can help create a baseline for safety inspections and condition monitoring.

Most importantly for Trafikverket, Hovermap captured the entire shaft quickly and safely, letting them get on with the business of keeping Sweden moving.

See how Brierley Associates are using Hovermap for safe road tunnel inspections with less disruptions in this case study.