Beyond the Surface: Emesent’s Innovative Approach to Convergence Monitoring in Underground Mines

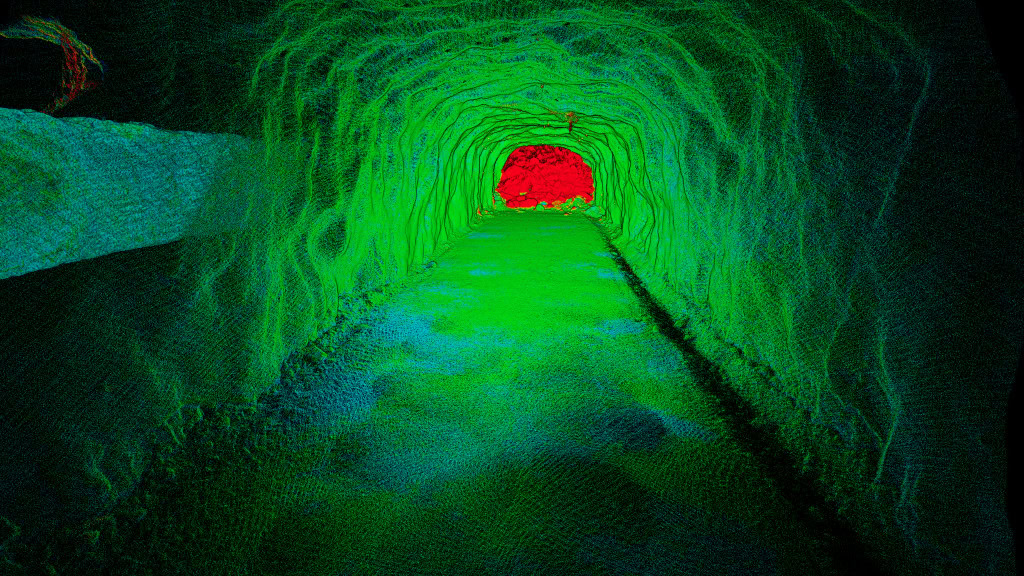

Monitoring rock displacement and movement in underground mining is critical for safety and operational efficiency. Traditional methods often lack comprehensive coverage and accuracy. Emesent has introduced an advanced solution using LiDAR and SLAM-based systems to enhance convergence monitoring in underground mines.

Emesent co-founder and CTO, Dr Farid Kendoul, explores how the Emesent team applied this technology to improve data accuracy and streamline the monitoring process, offering a more effective approach to identifying and managing potential issues.

By Dr Farid Kendoul

A NOVEL SOLUTION TO COMMON UNDERGROUND CHALLENGES

Underground mining poses unique challenges, particularly in monitoring rock displacement and movement, which can lead to serious consequences such as injuries and costly production delays, especially as mines go deeper.

Traditional methods like damage mapping, extensometers, and total stations have merits but often fall short in coverage, accuracy, and frequency. LiDAR 3D mapping technology offers a superior alternative for convergence monitoring, providing coverage and rich insights into rock movement and deformation in underground tunnels. However, for effective monitoring, the two scans (reference and new) must be aligned accurately to detect small movements and changes (e.g., 20mm movement or change). Misalignment or scan errors can lead to incorrect interpretations of deformation or convergence.

Currently, two main LiDAR scanning methods are used for underground convergence monitoring:

1. Terrestrial LiDAR scanners (TLS)

TLS systems provide highly accurate 3D data. When combined with Ground Control Points, they can build an accurate 3D model of large areas. However, the manual data collection process is time-consuming, often taking days to cover kilometers of tunnels and prepare data, limiting their use to critical small areas.

2. Mobile SLAM-based scanners

These scanners capture large underground areas efficiently within hours. However, SLAM systems can introduce inaccuracies (drift) in the 3D map. Some mines address this by scanning small areas or chopping large scans into smaller sections and using third-party software and manual steps for rigid alignment, which is time-consuming and limits widespread adoption.

Both methods rely on “rigid transformation” to align the reference and new scans. This process involves moving and rotating the new scan to fit the reference scan using methods like ICP (Iterative Closest Point). In rigid alignment, both reference and new scans remain unchanged, with only their location and orientation (transformation) adjusted. While this approach works well in ideal conditions where the scans are highly accurate and the only differences are environmental changes, it is not suitable for large-scale environments such as kilometers of tunnels. In such cases, inherent inaccuracies and potential drifts in the scans lead to misalignments, resulting in errors in detecting true deformations and convergence.

The Emesent team took on the challenge of developing a new convergence monitoring system that combines the benefits of LiDAR SLAM-based systems without the previously mentioned limitations. Their innovative approach leverages LiDAR and SLAM for efficient large-area scanning, enhanced with novel algorithms for automatically aligning extensive scans and delivering precise results.

At the heart of Emesent’s convergence monitoring system is its advanced SLAM technology, which allows for non-rigid (elastic or flexible) alignment of large scans that may have drift while maintaining local accuracy for convergence and change detection.

A MORE EFFECTIVE APPROACH TO CONVERGENCE MONITORING

Emesent’s Change Detection and Convergence Monitoring solution combines rapid-capture mobile SLAM technology with a faster, easier and more repeatable processing workflow. This enables mining operators to scan excavations over a larger area more regularly and monitor change using accurate, quantitative data.

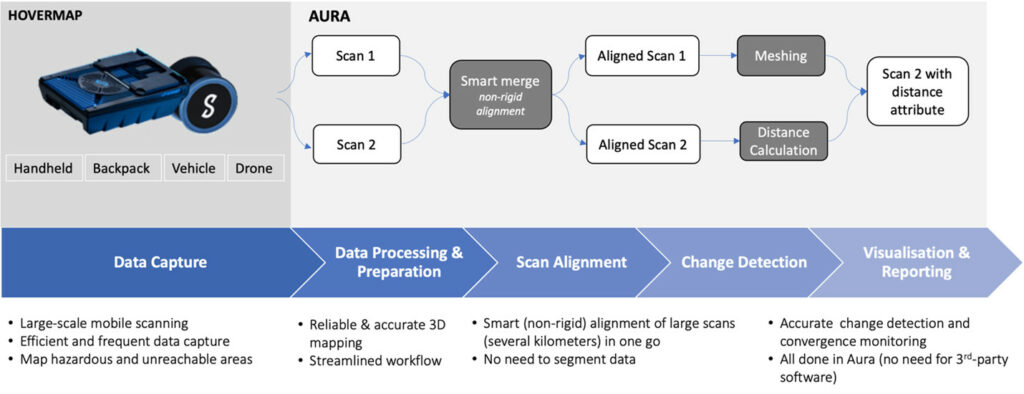

The solution combines two main Emesent products:

1. A Hovermap payload deployed via vehicle, backpack, drone or handheld to scan almost any area underground efficiently or even autonomously.

2. Aura desktop software for processing raw data, smart alignment of scans, comparing the scans and computing the change, visualizing the results and many other useful operations. Most of these workflows are automated, requiring minimal user inputs.

DELIVERING ACTIONABLE INSIGHTS THROUGH INNOVATION

Emesent’s convergence monitoring system represents a breakthrough in geotechnical monitoring, leveraging the advanced capabilities of Wildcat SLAM technology for intelligent, non-rigid (elastic and flexible) alignment of scans. In this innovative approach, the first scan is used as a reference and remains unchanged, while the second scan undergoes elastic modifications to align locally with the reference scan through non-rigid transformation. This process is based on the precise identification and matching of 3D features in both scans, effectively accounting for drifts and errors. Such local alignment is essential for accurately detecting changes and monitoring convergence in extensive areas and tunnels efficiently captured by a mobile SLAM mapping system.

This method allows for the precise alignment of extensive scans, such as kilometers of underground tunnels, achieving a high level of accuracy while eliminating the need for the tedious data segmentation process typically used to adjust for scan drift. Consequently, it enables the detection of deformations and changes as small as 5mm in specific areas and up to 15mm in typical underground environments.

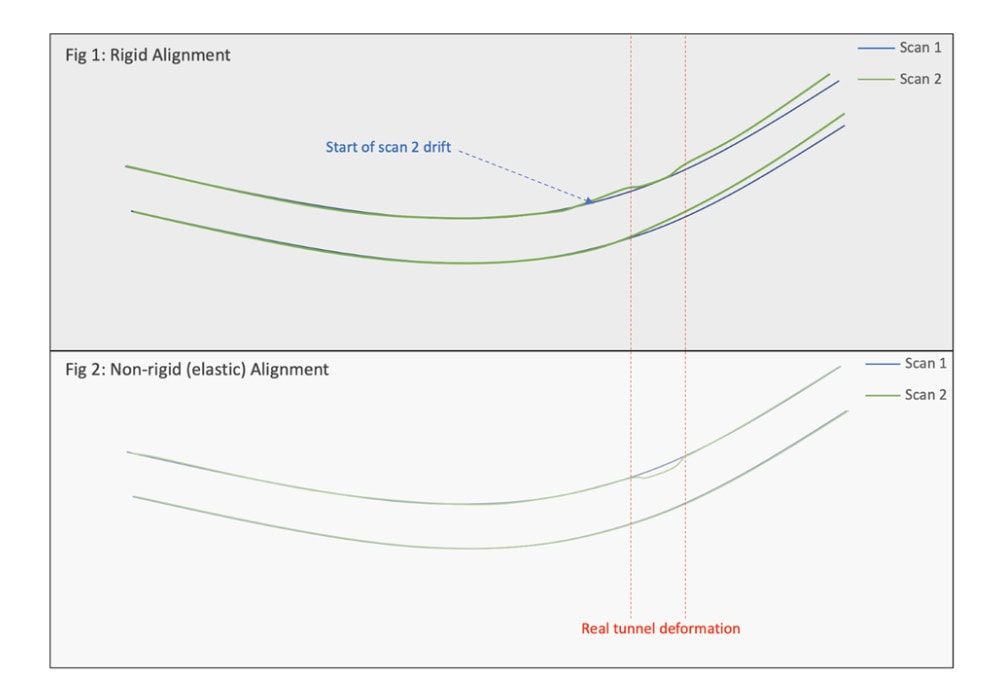

To showcase the benefits of this smart scan alignment, consider the example depicted in Fig 1 and Fig 2.

Scan 1, shown in blue, is the reference scan. Before taking Scan 2, shown in green, the tunnel experienced a small deformation highlighted in red. During the capture of Scan 2, drift occurred towards the end of the scan due to the accumulated errors of the SLAM system or errors in combining and georeferencing static scans.

In Fig 1, a rigid alignment of Scan 1 and Scan 2 masks the true tunnel deformation and instead estimates an apparent change due to scan drift.

In contrast, Fig 2 demonstrates that a smart non-rigid transformation accounts for drift and clearly highlights the true tunnel deformation as the difference between Scan 1 and Scan 2.

While the algorithm smartly handles local deformations, it is important to note that if an entire tunnel shifts globally in the second scan—a rare occurrence—the smart alignment will interpret this as drift in the SLAM scan data and deform it to align with the reference scan, thereby not detecting the global shift.

By combining this cutting-edge algorithm with the automated workflows in Aura, Emesent’s solution delivers a simplified, user-friendly workflow that eliminates the need for data segmentation or manual alignment. This makes it ideal for long scans of raises, tunnels, and other extensive underground areas. By removing the reliance on third-party software and minimizing user input, Emesent’s system offers a faster, more efficient workflow with repeatable and quantifiable outputs on where changes or dilations are occurring, and the velocity of these changes across large areas.

EMPOWERING INDUSTRY BEST PRACTICE

Emesent’s innovative convergence monitoring system not only enhances the safety and productivity of underground mining operations but also underscores the company’s leadership in mining technology. The combination of Wildcat SLAM technology and Aura software represents a transformative approach to geotechnical monitoring, offering unparalleled precision and efficiency.

As the mining industry continues to rapidly evolve, Emesent’s ongoing commitment to innovation will help drive improvements in operational safety and productivity.