-

Change Detection and Convergence Monitoring

Improve the coverage, frequency and reliability of your monitoring program to enhance operational safety and mitigate production delays.

-

Achieve greater visibility at scale to confirm stability

In underground mining rock mass displacement from an excavation can have significant consequences, from injuring personnel to causing unscheduled delays, with the subsequent cost implications.

In a mine you can rarely predict where things are going to change dramatically, therefore the ability to efficiently and effectively monitor change and convergence across the whole excavation is vital to safeguard against incidents and mitigate impacts on production and therefore profitability.

However, only a fraction of the cubic kilometers affected by the mining process are observable through drill holes or excavation fronts and therefore capturing sufficient data to be able to confirm that all areas of an excavation are stable can be challenging.

Additionally, processing the data to achieve analysis-ready outputs is a highly time consuming and manual process. As a result, many mining operations are falling short in the frequency and extent of their monitoring efforts, often unable to meet the standards they aspire to or that are necessary for optimal safety and operational efficiency.

The limitations of traditional methods

Currently, the predominant method for assessing change in underground mining is damage mapping, which entails annotating two-dimensional section views of the mine to highlight areas of damage. While this approach allows for coverage of a considerable area, it is subject to human error. Alternatively, tape or digital extensometers are used to measure specific points within the mine. Although these devices offer high levels of accuracy, due to the heterogeneous nature of rock masses, which exhibit varying properties across different locations within drives, tunnels, or cross-sections, the results cannot represent change across an entire excavation. More advanced technologies such as total stations or fixed laser sensors are highly accurate, however, they are constrained by limited coverage capabilities.

While each of these methods has its place, they also have their limitations. As a result, many underground mines fall short in the scale, frequency and reliability of their monitoring efforts, putting safety and profitability at risk.

Complementing traditional methods with SLAM

Complementing traditional practices with a SLAM methodology allows the implementation of an improved overall monitoring plan. For example, SLAM can quickly map an entire mine and identify displacement with moderate to high accuracy. This provides more accurate and quantitative data than damage mapping.

When it comes to tape extensometers, a SLAM map of an entire mine will allow you to pinpoint exactly where to use an extensometer in future to confirm that displacement. Or a total station could be used to identify change regarding specific infrastructure, for example a 1-2mm (about 0.08 in) shift at a mine entrance, but SLAM complements this by scaling to rapid mapping of large areas. Similarly, a fixed laser could be used to ensure a crusher chamber is not moving too much during stoping for example, but SLAM can be used to cover a wider area.

While many mines have used SLAM technology to scan the entire site and establish a baseline, alignment of these scans is a time consuming and manual process that usually requires the use of complex third-party software.

-

The Emesent Solution

Optimized for enclosed spaces and underground mines, and applicable to both hard rock (change detection) and soft rock (convergence monitoring) mines, Emesent’s Change Detection and Convergence Monitoring solution combines rapid capture mobile SLAM technology with a faster, easier and more repeatable processing workflow. This enables mining operators to scan excavations over a larger area more regularly and monitor change using accurate, quantitative data.

The solution eliminates the need for data segmentation, manual alignment or third party software and requires minimal user input. This ultimately delivers more repeatable, quantifiable outputs on where change or dilation is occurring and the velocity of this change over a large area. This can then be combined with other data to determine root cause analysis or identify why that change is occurring, allowing for more regular and widespread monitoring of change, helping engineers – from geotechs to surveyors – to make more informed decisions and reduce risk.

-

Rapid data capture

Rapidly capture current excavation profiles with Hovermap.

-

Streamlined workflow

Process, align and visualize changes between two Hovermap scans.

-

No 3rd-party software

Eliminates complex and time-consuming 3rd party software for alignment of scans.

-

Large-scale monitoring

Enables large scale and regular monitoring, delivering data to improve engineer decision making to reduce risk and hazard exposure.

-

Quantitative results

Allows quantitative and repeatable interpretation of deformation across an entire excavation.

-

No need to segment data

Compares scans of continuous 3D data at the same time. A non-rigid alignment process avoids segmentation to adjust for scan drift.

-

-

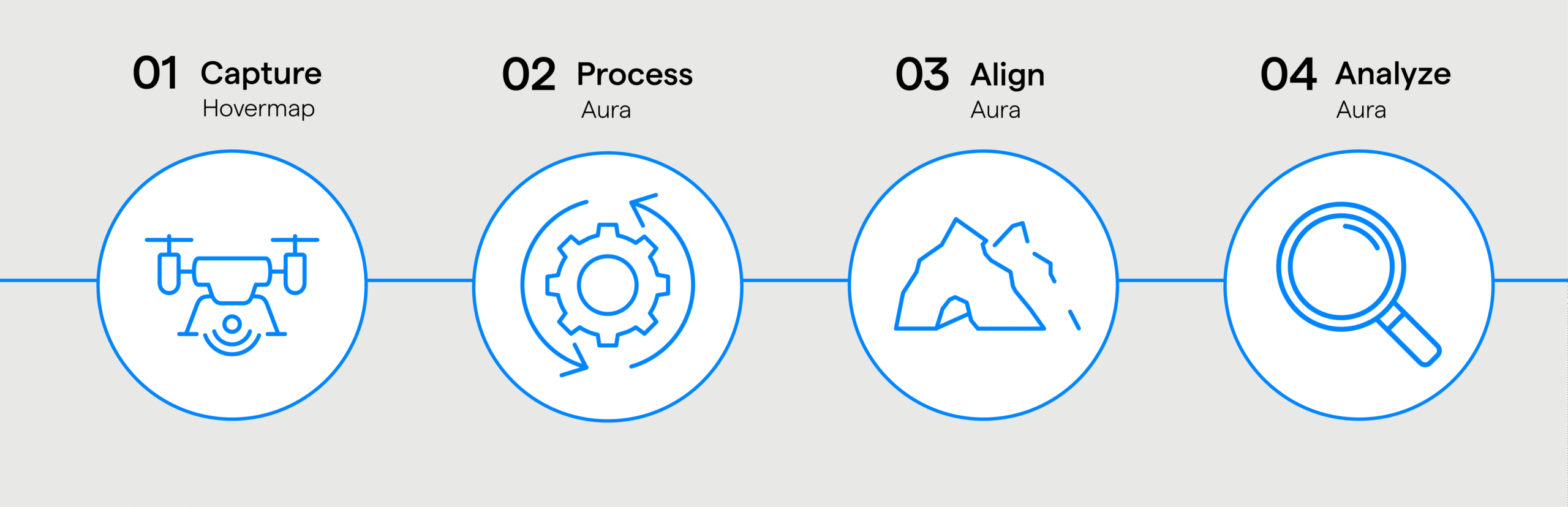

Operational workflow

- Take your reference scan and a subsequent scan.

- Process each scan with SLAM in Aura.

- Roughly align the two point clouds and let Aura compare both datasets.

- Interrogate the point cloud and mesh to see areas of movement between the two scans.

-

Improve your monitoring program

Rapid insights with applications across every type of underground mine that can be fed into a range of engineering processes.

-

Applications

Emesent Aura supports Change Detection and Convergence Monitoring for the following:

-

Whitepaper

Focus your geotechnical monitoring where it counts

Best practices to apply to optimize your convergence monitoring and change detection program. Download the whitepaper now.

-

Frequently Asked Questions

-

-

Want to see more?

Enquire Now